Advantages of Using Cobot Welding

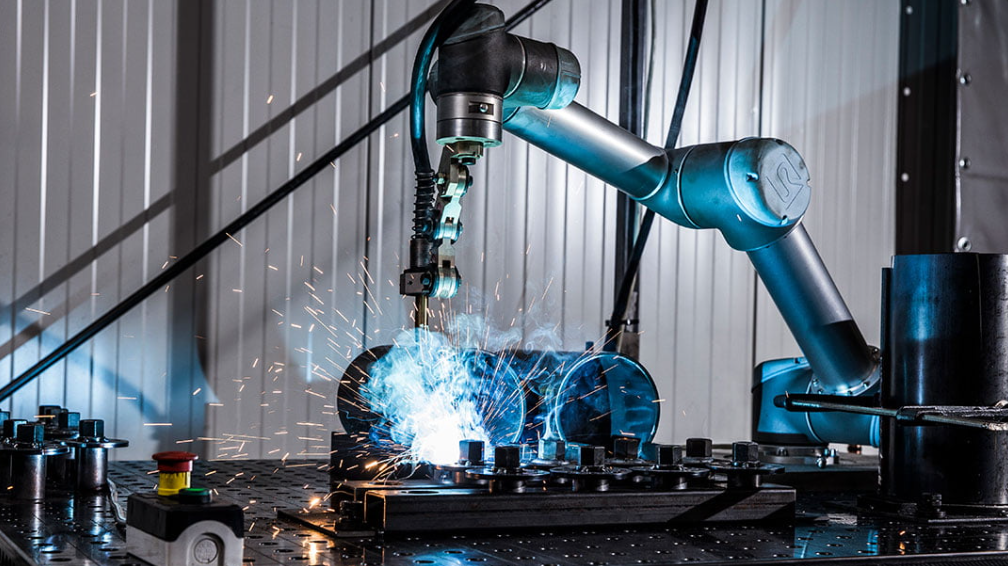

Cobot welding offers numerous advantages for modern manufacturing, combining precision, efficiency, and safety in ways traditional methods often cannot. By working collaboratively alongside human operators, these robots can handle repetitive or hazardous welding tasks while maintaining consistent quality. In this article, “Advantages of Using Cobot Welding,” we’ll explore the key benefits that make cobot welding a smart investment for production lines across various industries.

Advantage 1: Precision and Consistency

Cobot welding systems help manufacturers achieve precise and consistent welds. Cobots repeat the same movements every time, ensuring uniform welds and reducing errors that can happen with human welders. Unlike humans, cobots don’t get tired and can work continuously at a steady pace, producing reliable, high-quality results.

Advanced cobots with features like seam tracking and flexible movement can also handle complex welds accurately, even on parts with tricky shapes or positions.

Cobot welding improves precision, consistency, and reliability, making it a valuable tool in modern manufacturing.

Advantage 2: Enhanced Workplace Safety

Collaborative robots (cobots) make welding safer by taking on tasks that expose workers to heat, sparks, and toxic fumes. This keeps people at a safe distance and reduces the risk of burns, respiratory problems, and eye injuries. Cobots also help prevent physical strain by handling repetitive or physically demanding tasks that often require awkward positions, keeping workers healthier while maintaining productivity.

Equipped with safety sensors, cobots can detect obstacles or changes in their surroundings, allowing them to work safely alongside humans and avoid accidents.

Cobot welding improves workplace safety by protecting workers, reducing physical strain, and minimizing the risk of injuries.

See also: How Do 3D Billboards Work? Unveiling the Technology Behind the Visual Marvel

Advantage 3: Increased Productivity and Efficiency

Collaborative robots (cobots) help manufacturers work faster and more efficiently. They can run continuously without breaks, speeding up production and making better use of equipment. Unlike traditional robots that need safety cages, cobots can work safely alongside humans because of advanced sensors and controls, allowing more flexible workflows.

They handle repetitive tasks efficiently, reduce bottlenecks, and improve consistency. Cobot welding improves productivity and efficiency through faster operations, safe human collaboration, and smoother workflows.

Advantage 4: Flexibility and Adaptability

Collaborative robots (cobots) make manufacturing more flexible, which is helpful when production needs change. Modern cobots are easy to program and reprogram with simple, user-friendly controls. They work well for both small and large production runs. Cobots can handle varied tasks, like assembling automotive parts, while still performing precise jobs, such as welding large components.

Their compact design and compatibility with different welding processes make them easy to add to existing production lines. Cobot welding helps manufacturers adapt to changing production needs, manage different batch sizes efficiently, and maintain safe, high-quality operations.

Advantage 5: Cost-Effectiveness and ROI

Cobot welding helps manufacturers save money and quickly get a return on investment. Cobots reduce labor costs because they can replace several manual welders per shift, working continuously without breaks, overtime, or benefits. Their high precision also ensures consistent weld quality, which lowers defects, scrap, and rework costs.

Compared to traditional robotic welding systems, cobots are more affordable and easier to set up. Investing in cobot welding is cost-effective, cutting expenses while delivering fast returns and boosting efficiency in manufacturing.

Applications Across Industries

Collaborative robot (cobot) welding systems are improving manufacturing by increasing precision, safety, and efficiency. Here’s how they are used in key sectors:

- Automotive, Aerospace, and Industrial Machinery: Cobots are used for tasks like spot welding and assembling car panels in the automotive industry, ensuring accuracy and speed. In aerospace, they perform precise welding on aircraft parts like turbine blades and fuselage sections, reducing defects. Industrial machinery manufacturers use cobots to automate repetitive tasks, improving consistency and reducing human error.

- Metal Fabrication and Precision Components: In metal fabrication, cobots handle cutting, welding, and bending tasks, freeing workers to focus on complex work. For precision components in electronics and medical devices, cobots provide consistent weld quality essential for high reliability.

- Small and Medium-Sized Enterprises (SMEs): SMEs adopt cobots because they are affordable, easy to integrate, and require less infrastructure than traditional automation. This makes cobots a cost-effective solution for smaller operations.

Cobot welding is enhancing manufacturing across multiple sectors by delivering precise, safe, and efficient production, improving both quality and productivity.

Training Requirements and Ease of Adaptation for Cobot Welding

To work effectively with welding cobots, operators need a mix of technical knowledge, practical experience, and continuous learning:

- Robotics Training: Operators should complete manufacturer-specific courses or online modules to understand how the cobot works, how to program it, and how to use it safely and efficiently.

- Welding Experience: Operators should have at least three years of hands-on welding experience. This helps them understand different techniques, materials, and processes, ensuring high-quality welds.

- Safety Knowledge: Operators need to understand safety rules and know how to check for risks. This helps prevent accidents and keeps them and others safe while working with cobots.

- Programming Skills: Comfort with programming tools, like teach pendants and hand-guiding methods, allows operators to set up tasks, adjust movements, and optimize the cobot for specific jobs.

- Advanced Integration: Knowledge of features like seam tracking, adaptive welding sensors, and other automated equipment helps maximize efficiency and accuracy.

- Maintenance Understanding: Regular checks, cleaning, and part replacements are needed to keep the cobot running reliably and prevent downtime.

- Troubleshooting: Troubleshooting means spotting and fixing cobot problems quickly to keep them running smoothly, avoid interruptions, and prevent production delays.

- Continuous Learning: Staying updated on new cobot technologies, software updates, and welding techniques is essential for maintaining high-quality and efficient operations.

Adapting to cobot welding requires a combination of welding skills, robotics training, safety awareness, maintenance knowledge, and ongoing learning. Having the right skills allows operators to safely and efficiently use cobots, ensuring reliable, high-quality welds.

Future Potential

Cobot welding is rapidly evolving with AI, machine learning, and Industry 4.0 technologies. Here’s what to expect:

- Smarter, More Autonomous Cobots: AI and machine learning (ML) enable cobots to work more independently and handle complex tasks. In welding, AI can monitor real-time data and automatically adjust the robot’s settings. This helps improve weld quality, reduce defects, and make production more efficient.

- Integration with Industry 4.0: Connecting cobots to Industry 4.0 systems allows them to work as part of a smart factory. This means manufacturers can monitor operations remotely, predict when maintenance is needed, and coordinate cobots efficiently with other machines, improving overall productivity and reducing downtime.

- Enhanced Human-Robot Collaboration: Cobots are designed to work safely alongside humans. They assist with repetitive or physically demanding tasks, reducing worker strain and letting humans focus on more complex work. This is especially helpful in industries with labor shortages or hazardous conditions.

The future of cobot welding promises smarter robots, seamless integration into connected factories, and closer collaboration with humans, leading to safer, more flexible, and efficient manufacturing.

Conclusion

Collaborative robot (cobot) welding is revolutionizing modern manufacturing by combining precision, safety, productivity, and flexibility. Cobots deliver consistent, high-quality welds, minimize human error, and enhance product reliability. Their adaptability allows them to handle a wide range of tasks and production scales.

Investing in cobot welding provides manufacturers with cost savings, improved quality, and a safer work environment. With user-friendly interfaces and easy deployment, even small and medium-sized enterprises can benefit.

By adopting cobot technology, companies position themselves at the forefront of manufacturing innovation, enhancing operational efficiency and maintaining long-term competitiveness in a rapidly evolving industry.